Automobile sheet metal parts are an important part of an automobile body.

The following is a detailed introduction to automobile sheet metal parts:

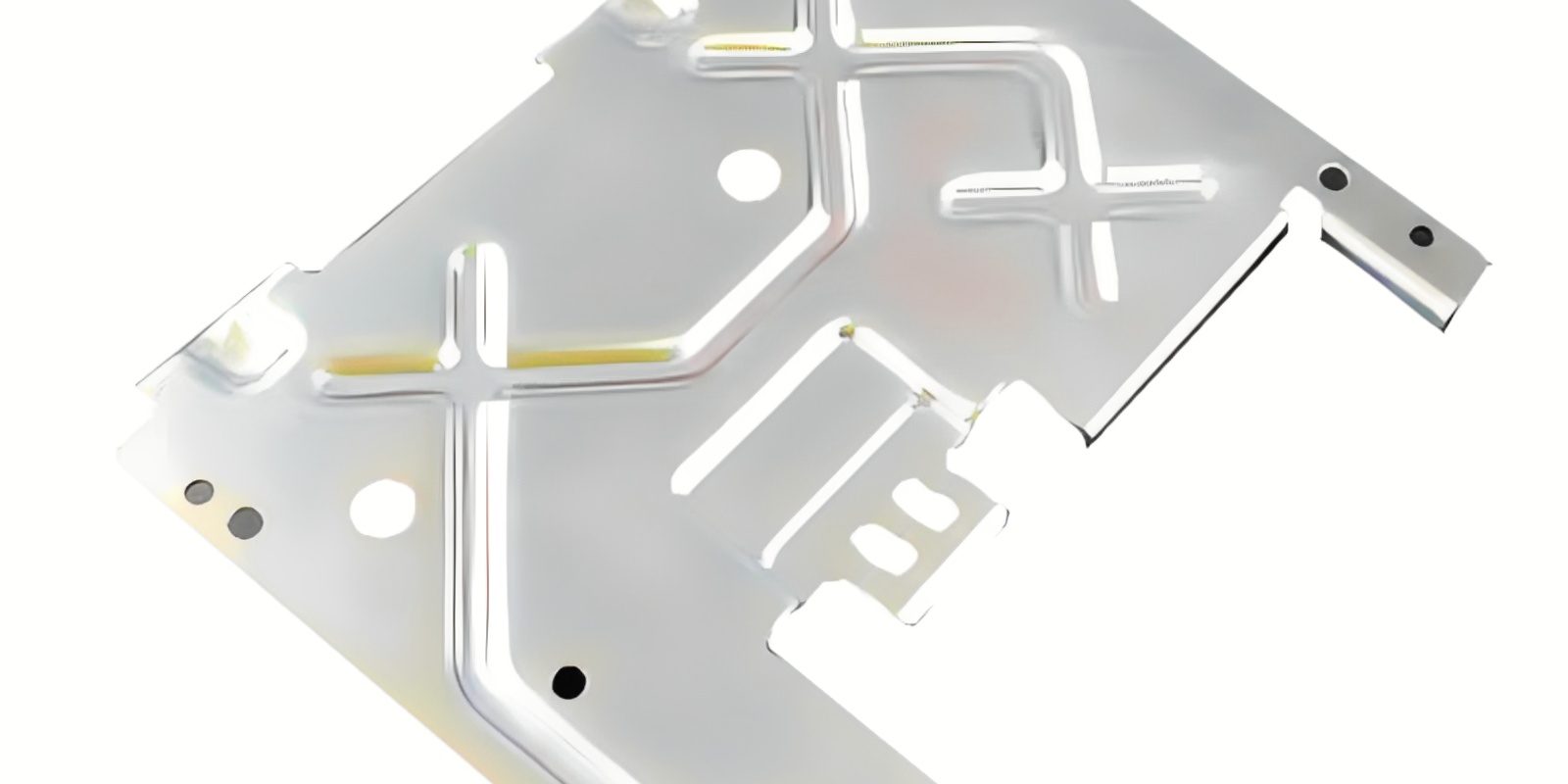

**I. Definition and Function** Automobile sheet metal parts refer to parts processed for the metal shell of an automobile, including body panels and structural parts. Its main functions are as follows:

1. Forming the automobile shape: Sheet metal parts shape the unique appearance of an automobile through different shapes and combinations.

2. Providing protection: Protecting the mechanical parts, electrical systems and passengers inside the automobile from the impact, collision and adverse environmental influences from the outside. 3. Enhancing body strength: Working together with structures such as the frame to improve the overall strength and rigidity of the automobile and ensure safety during driving.

**II. Common Types**

1. Body panels – Hood: Located at the front of the automobile to protect components such as the engine. Usually made by stamping thin steel plates and having certain strength and rigidity. – Doors: Including front and rear doors, used for passengers to enter and exit and protect people inside the car. Doors are usually composed of inner panels, outer panels, reinforcing beams, etc. – Trunk lid: Located at the rear of the automobile and used for storing luggage. The structure of the trunk lid is similar to that of the hood and is also made by stamping thin steel plates. – Fender: Installed above the automobile wheels and playing a role in protecting the wheels and the side of the body. Fenders are usually made of plastic or thin steel plates.

2. Body structural parts – Frame: It is the skeleton of an automobile and bears various loads of the automobile. The frame is usually welded by high-strength steel and has high strength and rigidity. – Crossbeam: Connecting various parts of the frame to enhance the stability and strength of the body. Crossbeams are usually made of materials such as steel pipes or channel steels. – Pillars: Including A-pillars, B-pillars, C-pillars, etc., supporting the roof and the side of the body and protecting people inside the car. Pillars are usually made of high-strength steel.

**III. Manufacturing Process**

1. Stamping – Stamping is one of the main processes for manufacturing automobile sheet metal parts. Metal sheets are stamped into the required shapes and sizes through molds. The stamping process has the advantages of high production efficiency, high precision and low cost. – During the stamping process, appropriate molds and stamping equipment need to be selected according to the shape and size of the sheet metal parts. At the same time, parameters such as stamping pressure, speed and temperature need to be controlled to ensure the quality of sheet metal parts.

2. Welding – Welding is an important process for connecting stamped sheet metal parts. Commonly used welding methods include resistance welding, gas shielded welding, laser welding, etc. – During the welding process, it is necessary to ensure the strength and tightness of the weld, and at the same time control the welding deformation and residual stress. In order to improve the welding quality, advanced welding technologies and equipment such as robot welding and laser welding can be adopted.

3. Coating – Coating is to protect the surface of sheet metal parts and improve their corrosion resistance and aesthetics. The coating process includes pretreatment, primer, intermediate coat and topcoat. – Pretreatment mainly removes impurities such as oil stains and rust on the surface of sheet metal parts to provide a good foundation for subsequent coating. Primer and topcoat play the roles of anti-corrosion and aesthetics respectively. The intermediate coat can increase the thickness and hardness of the coating and enhance the wear resistance and impact resistance of the coating.

**IV. Repair and Maintenance**

1. Repair – When an automobile collides or is scratched, sheet metal parts may be damaged. At this time, sheet metal repair is required, including shaping, welding, painting and other links. – Sheet metal repair requires professional technology and equipment to ensure that the repaired sheet metal parts can restore to their original shape and performance. At the same time, attention should also be paid to safety issues during the repair process to avoid accidents such as fire and explosion.

2. Maintenance – In order to prolong the service life of automobile sheet metal parts, regular maintenance is needed. Maintenance contents include cleaning, waxing, rust prevention treatment, etc. – Cleaning can remove dust, dirt and other impurities on the surface of sheet metal parts and maintain their surface finish. Waxing can form a protective film on the surface of sheet metal parts to prevent them from being eroded by ultraviolet rays, acid rain, etc. Rust prevention treatment can prevent sheet metal parts from rusting and prolong their service life. In conclusion, automobile sheet metal parts are an important part of an automobile body. Their quality and performance directly affect the safety, comfort and aesthetics of an automobile. When choosing and using automobile sheet metal parts, attention should be paid to their quality and performance. At the same time, regular repair and maintenance should be carried out to ensure the normal operation of the automobile.