Automobile sheet metal parts are an important part of an automobile body. The following is a detailed introduction to automobile sheet metal parts:

**I. Definition and Function** Automobile sheet metal parts refer to parts that process and repair the metal shell of an automobile, mainly including body panels and structural parts.

1. Body panels: such as doors, engine hoods, trunk lids, fenders, etc. These components mainly play the role of protecting the people and equipment inside the car and improving the appearance of the car.

2. Structural parts: such as frames, crossbeams, columns, etc. Structural parts are the skeleton of a car and play an important role in supporting the body, transmitting power and bearing loads.

**II. Material Characteristics**

1. High strength: In order to ensure the safety and stability of a car during driving, automobile sheet metal parts usually use high-strength steel, aluminum alloy and other materials. These materials have high strength and stiffness and can withstand greater impact force and load.

2. Corrosion resistance: Cars will be affected by various environmental factors during use, such as rain, moisture, salt, etc. Therefore, automobile sheet metal parts need to have good corrosion resistance to prolong their service life.

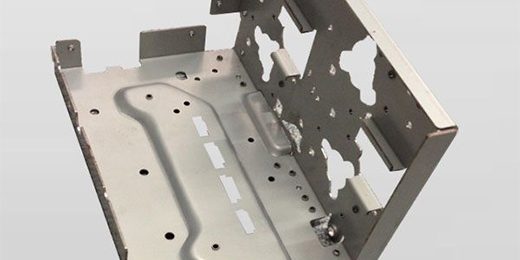

3. Processability: Automobile sheet metal parts need to go through various processing technologies such as stamping, welding, and bending to take shape. Therefore, the material needs to have good processability to facilitate the manufacture of parts of various shapes and sizes.

**III. Manufacturing Process**

1. Stamping: Stamping is one of the most commonly used processes in the manufacture of automobile sheet metal parts. Sheets are stamped into various shapes of parts such as doors and engine hoods through molds. The stamping process has the advantages of high production efficiency, low cost, and high precision.

2. Welding: Welding is an important process for connecting multiple sheet metal parts. Common welding methods include resistance welding, gas shielded welding, laser welding, etc. The welding process needs to ensure the strength and tightness of the weld to ensure the safety and reliability of the car.

3. Bending: Bending is a process of bending a sheet into a certain angle. Sheets are bent into various shapes of parts such as frames and crossbeams through a bending machine. The bending process needs to ensure the accuracy of the bending angle and the surface quality of the sheet.

**IV. Repair and Maintenance**

1. Repair: When a car collides or is scratched, the automobile sheet metal parts may be damaged. At this time, sheet metal repair is required. Sheet metal repair usually includes the following steps: – Assess the degree of damage: Assess the degree of damage to the automobile sheet metal parts and determine the repair plan. – Remove damaged parts: Remove the damaged sheet metal parts for repair. – Plastic repair: Use professional tools to perform plastic repair on the damaged sheet metal parts to restore them to their original shape and size. – Welding and painting: Perform welding and painting treatment on the repaired sheet metal parts to make their surface smooth and beautiful.

2. Maintenance: In order to prolong the service life of automobile sheet metal parts, regular maintenance is required. Maintenance measures include: – Cleaning: Clean the car regularly to remove dirt and impurities on the body surface to prevent corrosion. – Waxing: Wax the car regularly to protect the body surface and prevent scratches and oxidation. – Avoid collisions: During driving, pay attention to avoiding collisions and scratches to reduce damage to automobile sheet metal parts. In conclusion, automobile sheet metal parts are an important part of an automobile body. Their quality and performance directly affect the safety, reliability and appearance of a car. When using and maintaining a car, pay attention to the maintenance and repair of automobile sheet metal parts to ensure the normal operation and service life of the car.