ZenaTech, founded in 1990 by name “Yueqing Zhongde”, is a different kind of manufacturing company in China. We are specialized in making custom metal and plastic parts, Such as:

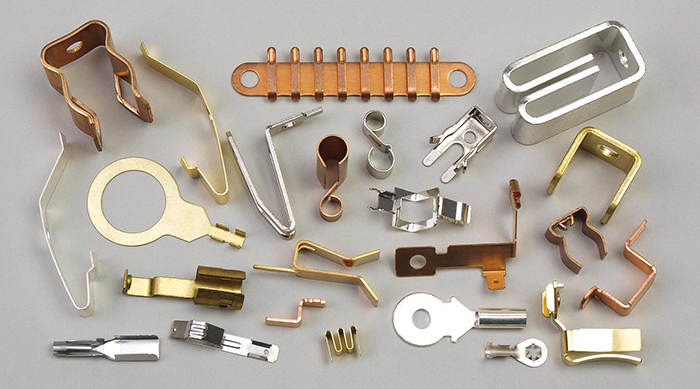

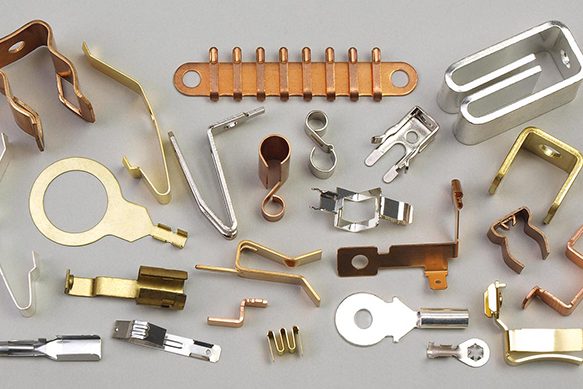

- Custom Spring: For instance, Compression Spring, Extension Spring, Torsion Spring, and Wire Forming

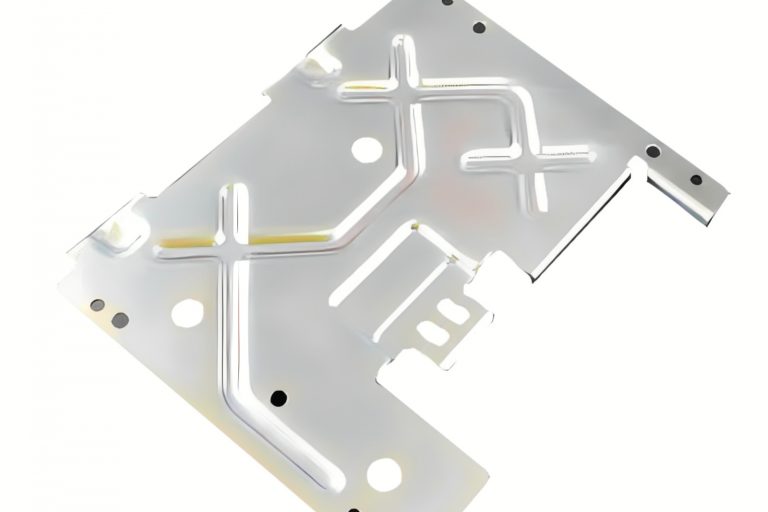

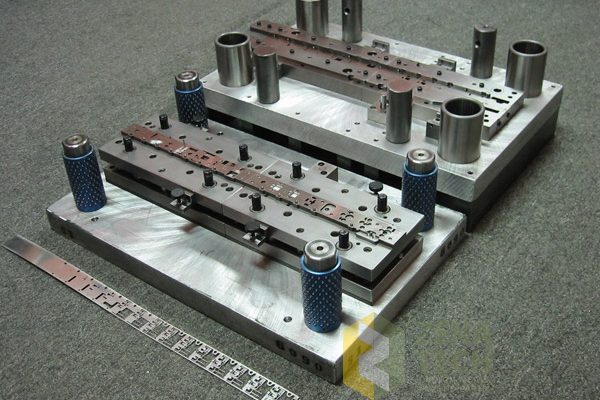

- Custom-made Stamping Part: Such as, Metal Stamping Part, Sheet Stamping Part, Die, and Bracket

- Custom Plastic Injection Part: Such as, Plastic Injection Mold, and Plastic Part

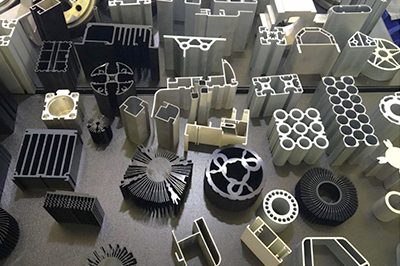

- Custom Machining Part: For example, CNC Machining part, Standoff, Screw, CNC Turnning part, and Lathe part

- Custom-built Assembly service: For instance, Metal Part Assembled with Plastic Part, Tape and Reel Assemble