The processing technology of stamping parts is mainly blanking, bending and stretching. These processes are widely used and involve all aspects of our daily life. Good stamping process can achieve the purpose of saving materials, improving die life, product quality and production efficiency.

Introduce the three kinds of technology

1. Drawing process;

The fillet half pass R of the boss and the side wall and the fillet R of the bottom and the side wall should be as large as possible. The larger the fillet half pass is, the easier the stretch is to be stretched. The stretch should be symmetrical as far as possible or adopt the upper and lower symmetry of the stretch; Easy to stretch in pairs, then cut into two pieces;

2. Bending process;

When bending to avoid the deformation of the hole, the hole edge and the bending place should be appropriate spacing, in order to prevent the deformation of the hole, otherwise, bending and then punching; The length of the curved edge should not be too small; As far as possible, the pressing and bending parts should take into account the precise positioning of the process holes and the pressing and bending in pairs to change the bearing condition;

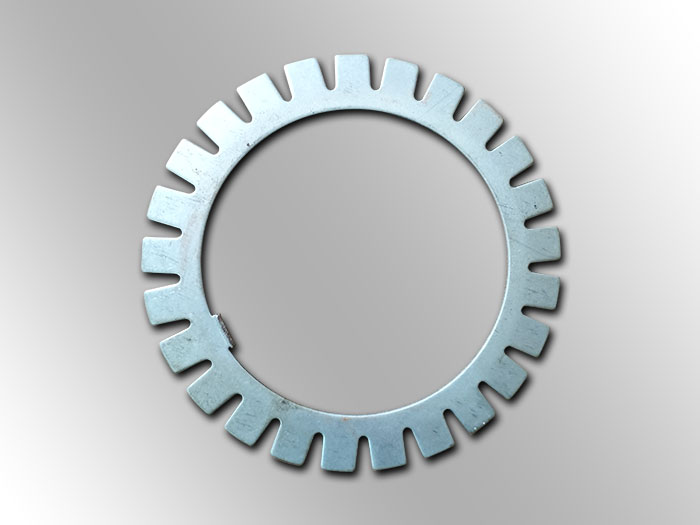

3. Blanking process;

The appearance should be as far as possible to make effective layout of raw materials, improve the utilization rate of materials, parallel lines or curves should be properly rounded, in order to facilitate the production, maintenance and application of the mold; Prevent too long slender appearance design; Diameter and hole position should be in accordance with the size of the drawing.