Metal Stamping is a kind of forming processing method which uses press and die to exert external force on sheet, strip, pipe and profile to produce plastic deformation or separation, so as to obtain the required shape and size of the workpiece (stamping part). Stamping and forging belong to plastic processing (or pressure processing), collectively known as forging. The stamping blank is mainly hot-rolled and cold-rolled steel plate and strip. 60-70% of the world’s steel is plate, and most of them are made into finished products by stamping. The automobile body, chassis, oil tank, radiator, boiler drum, container shell, motor, electrical appliance iron core, silicon steel sheet are all processed by stamping.

There are also a large number of stamping parts in instruments, household appliances, bicycles, office machinery, living utensils and other products.

Stamping processing is a kind of production technology which can make the sheet metal directly subject to the deformation force and deform in the die with the help of the power of conventional or special stamping equipment, so as to obtain the product parts with certain shape, size and performance. Sheet metal, die and equipment are the three elements of stamping. According to the stamping processing temperature, it is divided into hot stamping and cold stamping. The former is suitable for sheet metal processing with high deformation resistance and poor plasticity, while the latter is carried out at room temperature, which is a common stamping method for sheet metal. It is one of the main methods of metal plastic processing (or pressure processing), and also belongs to the material forming engineering technology.

The die used in stamping is called stamping die, referred to as stamping die. Stamping die is a special tool for batch processing materials (metal or nonmetal) into required stamping parts. The stamping die is very important in stamping. If there is no die that meets the requirements, it is difficult to carry out the batch stamping production; without the advanced die, the advanced stamping process can not be realized. Stamping process and die, stamping equipment and stamping materials constitute the three elements of stamping process, only when they are combined can stamping parts be obtained. Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can produce stiffeners, stiffeners, etc

Stamping Part ,Stamping Parts Manufacturer

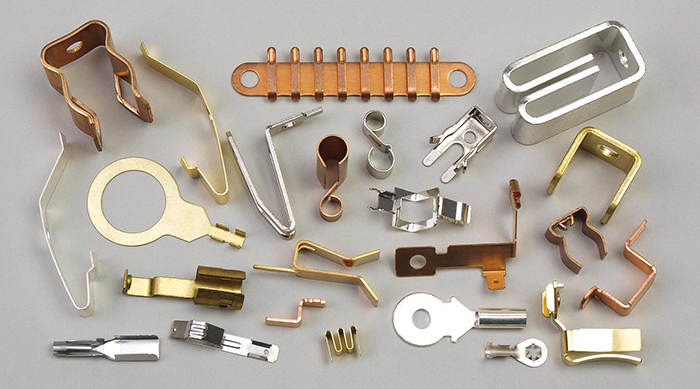

Stamping parts

Due to the use of precision die, the precision of the workpiece can reach micron level, and the repetition precision is high, and the specifications are consistent, so the holes and boss can be punched. Generally, cold stamping parts are no longer machined, or only need a small amount of cutting. The accuracy and surface state of hot stamping parts are lower than those of cold stamping parts, but they are still better than castings and forgings, and the cutting amount is less.

Stamping is an efficient production method. Using compound die, especially multi position progressive die, multiple stamping processes can be completed on one press (single station or multi station), so as to realize automatic production from strip uncoiling, leveling, blanking to forming and finishing. High production efficiency, good working conditions, low production costs, generally can produce hundreds of pieces per minute. Compared with other methods of mechanical processing and plastic processing, stamping has many unique advantages in both technical and economic aspects

Stamping tee

The main performance is as follows.

(1) The production efficiency of stamping process is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because stamping depends on the stamping die and stamping equipment to complete the processing, ordinary press stroke times can reach dozens of times per minute, high-speed pressure can reach hundreds or even more than 1000 times per minute, and each stamping stroke may get a stamping part.

(2) as like as two peas are used to ensure the stamping parts’ surface quality, the die life is generally longer. The stamping quality is stable and interchangeability is good, and it has the same characteristics.

(3) Stamping can produce parts with large size range and complex shape, such as the second hand of a clock or watch, a large part of a car’s longitudinal beam and covering parts. In addition, the cold deformation hardening effect of the material during stamping makes the stamping strength and rigidity higher.

(4) Generally, there is no chip and broken material in stamping, the consumption of material is less, and other heating equipment is not needed. Therefore, stamping is a kind of material saving and energy-saving processing method, and the cost of stamping parts is low.

Because stamping has such advantages, stamping processing is widely used in various fields of national economy. For example, in aerospace, aviation, military industry, machinery, agricultural machinery, electronics, information, railway, post and telecommunications, transportation, chemical industry, medical equipment, daily electrical appliances and light industry departments have stamping processing. Not only does the whole industry use it, but everyone has direct contact with stamping products. Like airplanes, trains, cars, tractors, there are many large, medium and small stamping parts. Car body, frame and rim and other parts are stamping out. According to the relevant investigation and statistics, 80% of bicycles, sewing machines and watches are stamping parts; 90% of TV sets, tape recorders and cameras are stamping parts; there are also metal food cans, steel precision boilers, enamel pots and bowls and stainless steel tableware, all of which are stamping products using molds; even computer hardware can not lack stamping parts.